Polished Concrete

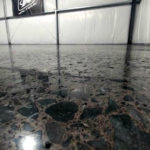

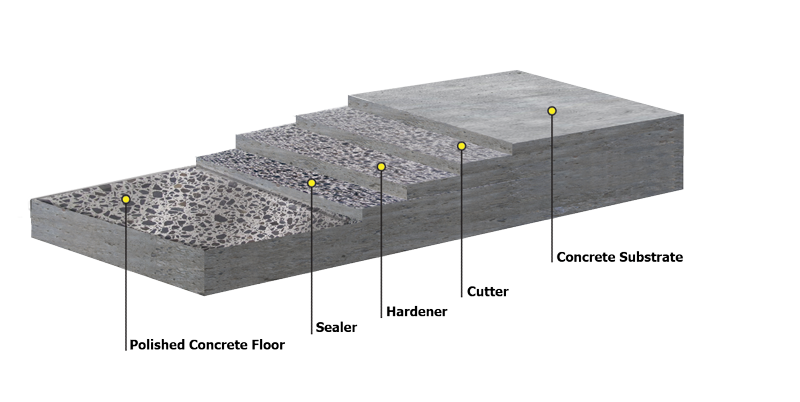

Polished concrete is a mechanical grind and polish process that utilizes industrial diamonds & impregnating hardeners and sealers to level, densify, polish, and seal concrete floor. Polishing brings out the natural beauty of concrete by smoothing the surface.

In addition to its extensive life cycle and cost efficiency, polished concrete floors offer a number of benefits. Multiple grinding stages smooth concrete to a smooth high luster finish. Aggregates, dyes, acid staining, and graphics provide limitless options to provide a luxury finish. The Concrete Protector teaches the grinding and polishing process and stock all equipment, tooling, and chemicals need to create this modern floor surface.

We teach the process and stock all of the equipment, tooling, and chemicals for this modern floor surface. LEED qualified and preferred by World Class Companies, Retailers, Hospitals, Churches, Schools, and Government Buildings, large concrete areas can be transformed into clean, colorful, functioning flooring, using the The Concrete Protector polishing techniques.

Polished Concrete Applications

- Warehouses (distribution centers, shipping and receiving)

- Factories (power plants and manufacturing plants)

- Institutional Flooring (schools and universities, hospitals, museums, churches, nursing homes, jails and prisons, fire stations, stadiums, municipalities.)

- Military Buildings (aircraft hangar, military commissary)

- Manufacturing (automobile, food and beverage, pharmaceutical)

- Retail (drugstore, dollar store, beer and wine store, beverage, hardware store, auto parts store, big box store, grocery stores)

- Residential